Choosing the right insulation for your home is one of the most important steps in improving comfort and energy efficiency. For many homeowners in New York and Pennsylvania, blown-in insulation is a preferred option because it can be applied in attics, wall cavities, and other hard-to-reach spaces. Two of the most common choices are fiberglass and cellulose blown-in insulation.

While both materials share the goal of regulating indoor temperatures and reducing energy costs, they differ in composition, installation, performance, and long-term value. Understanding these differences helps homeowners make informed decisions that fit their unique needs.

This guide breaks down how fiberglass and cellulose compare, highlights their strengths and limitations, and offers insights into which might be best for your property.

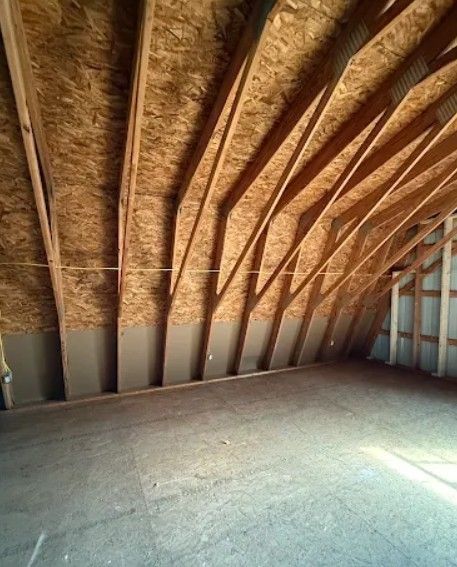

What Is Blown-In Insulation?

Blown-in insulation refers to loose-fill material that is installed using specialized equipment. The insulation is literally “blown” into cavities, attics, or between joists, filling gaps and covering irregular spaces that batt insulation might miss.

Because it adapts to different spaces, blown-in insulation is ideal for retrofits in older homes as well as upgrades in newer properties. In regions like New York and Pennsylvania, where weather conditions vary dramatically, blown-in insulation provides a strong balance of coverage and performance.

Fiberglass Blown-In Insulation

Fiberglass insulation is made from fine strands of glass that are spun into fibers. For blown-in applications, these fibers are loose and applied with blowing machines to create a thick, fluffy layer.

Benefits of Fiberglass

- Thermal efficiency: Fiberglass offers solid thermal resistance, which helps lower heating and cooling costs year-round.

- Non-combustible: Fiberglass is naturally fire-resistant, providing peace of mind in terms of safety.

- Durability: When installed correctly, fiberglass maintains its performance over time without significant settling.

- Moisture resistance: Fiberglass does not absorb water, making it less likely to support mold growth.

Limitations of Fiberglass

- Air sealing: Fiberglass does not naturally seal air leaks, so its effectiveness depends on thorough coverage.

- Installation quality: Poorly installed fiberglass can leave gaps that reduce performance.

- Comfort during install: Fibers can irritate skin and lungs if not handled with care, which is why professional installers are recommended.

If you are looking for an experienced fiberglass insulation installer, a professional application ensures that the material is spread evenly and delivers full thermal performance.

Cellulose Blown-In Insulation

Cellulose insulation is primarily made from recycled paper products treated with fire-retardant chemicals. It is also applied using blowing machines, creating a dense and consistent layer.

Benefits of Cellulose

- Eco-friendly: Cellulose is one of the most environmentally friendly insulation materials due to its high recycled content.

- Airflow resistance: Its dense structure helps slow airflow, which can improve thermal efficiency.

- Sound absorption: Cellulose offers better soundproofing qualities than fiberglass in many cases.

- Affordability: Cellulose often costs less upfront compared to fiberglass.

Limitations of Cellulose

- Moisture absorption: Cellulose can absorb water, and if it becomes damp, it may lose effectiveness and increase the risk of mold.

- Settling over time: Cellulose tends to settle more than fiberglass, which can reduce insulation depth and performance.

- Weight: Its heavier density may not be ideal in all attic spaces.

When considering acellulose insulation installer, make sure they understand local building conditions and can properly assess whether cellulose is the right choice for your home.

Comparing Fiberglass and Cellulose

When weighing fiberglass against cellulose, it helps to consider the following factors:

Energy Efficiency

Both options deliver solid thermal performance. Fiberglass is known for consistency over time, while cellulose provides excellent initial coverage but may settle.

Moisture Performance

Fiberglass resists moisture better than cellulose, making it a safer long-term option in humid or damp conditions often found in Pennsylvania basements or New York coastal areas.

Fire Resistance

Fiberglass is naturally non-combustible, while cellulose relies on chemical treatments for fire resistance. Both can meet safety requirements when properly installed.

Environmental Impact

Cellulose has the edge here because of its recycled content. For eco-conscious homeowners, this can be a deciding factor.

Soundproofing

Cellulose provides slightly better noise control because of its dense structure, which makes it popular in urban neighborhoods or near high-traffic roads.

Cost

Cellulose is usually less expensive upfront, while fiberglass may offer better long-term stability with fewer performance concerns.

Installation and Professional Expertise

Whether you choose fiberglass or cellulose, the quality of installation makes all the difference. Even the best materials fail to perform if gaps, uneven coverage, or settling issues occur.

That is why working with experienced insulation professionals is essential. In New York and Pennsylvania, trained crews understand the unique challenges of older homes, climate differences, and code requirements. Professional installers also ensure that blown-in insulation is applied evenly and at the proper depth to meet energy goals.

Local Considerations for New York and Pennsylvania

Homes in these states face varied conditions. Northern Pennsylvania often deals with heavy snowfall and cold winters, which demand strong thermal resistance. Coastal and urban areas of New York may experience higher humidity, making moisture resistance critical.

Fiberglass may be the safer choice for homes with greater moisture risks, while cellulose may be appealing for eco-conscious homeowners who want effective soundproofing in denser neighborhoods. In either case, blown-in insulation provides a significant upgrade to comfort and efficiency.

Long-Term Value of Blown-In Insulation

Both fiberglass and cellulose deliver strong returns by lowering energy bills, improving comfort, and enhancing resale value. Over the lifespan of a home, the initial investment is often outweighed by reduced utility costs and fewer temperature-related issues.

For families looking to improve both comfort and efficiency, consulting with a skilled fiberglass insulation installer or cellulose insulation installer can help determine which material will perform best in their specific property.

Final Thoughts

The choice between fiberglass and cellulose blown-in insulation depends on your priorities. Fiberglass offers durability, moisture resistance, and fire safety. Cellulose provides eco-friendly benefits, soundproofing, and a lower upfront cost.

For homeowners in New York and Pennsylvania, the right option often comes down to balancing climate, budget, and personal preferences. With professional installation, either choice will contribute to a quieter, more comfortable, and energy-efficient home.